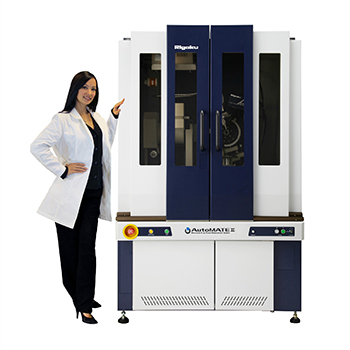

AutoMATE II

A highly accurate micro-area residual stress suited to both iso and side inclinations methods.Residual stresses in a material can have a detrimental impact on a components life. These residual stresses may be induced during the production or forming procedure or may even accumulate during service. An important part of quality control is being able to detect these stresses which can also be used to predict the lifetime of the component.The ability to measure such stresses has traditionally been the realm of research x-ray diffractometers with highly accurate goniometers. Such systems typically have restrictions on the size of the sample that they are able to measure. While factory-floor and dedicated residual stress analysers capable of analysing larger samples do exist, their mechanical design is often associated with reduced accuracy.The AutoMATE II combines the best of both research and dedicated systems. The system can handle large parts up to 30kg in weight with the standard Z stage, while samples up to 20kg are possible using the optional automated XYZ stage. Accurate measurements are possible as the x-ray source and detector arm are mounted on a highly accurate two-axis goniometer that can be positioned relative to the measurement site and can operate with an accuracy of 0.1 microns when used in conjunction with the XYZ stage.

X-Ray Detector

The AutoMATE II also benefits from the latest and most innovative x-ray detector, the D/tex Ultra1000, an electric Si strip detector with high dynamic range, high sensitivity, good energy resolution and no requirement for consumable gas.

Applications

The AutoMATE II x-ray diffractometer is suited to measuring residual stresses in such things as:

- Shot peened springs

- Around weld beads

Key Features

Key features of the Rigaku AutoMATE II system include:

- Highly accurate goniometer facilitating true-micro area stress measurement

- Goniometer capable of iso and side inclination methods automatically without the need to adjust sample position

- Automated mapping measurements with teaching function

- Capability for measuring large heavy samples with high accuracy

- Measurement system controlled by a CCD camera with microscope with zoom function

- Enclosed radiation chamber tat locks when the x-ray shutter is open