Measuring the Carbon Content of Steel Using a Handheld LIBS Low Alloy and Carbon Steels

Knowledge of the carbon content in low alloy and carbon steels is of great importance to be able to classify and identify them. The carbon content also has a marked effect on the properties of the steel. For instance, plain carbon steels can be divided into several groups:

- Very low carbon content steels Carbon content <0.05, typically ductile with properties similar to iron. While inexpensive they are restricted to use in non-structural applications e.g. panelling

- Low carbon content steels Carbon content 0.05-0.2%, make up the bulk of the general purpose steels with common applications including automotive bodywork, ships and domestic appliances

- Medium carbon content steels Carbon content 0.2-0.5%, also very commonly used, in applications requiring more strength than low carbon steels e.g. gears, pylons and pipelines

- Medium-high carbon content steels Carbon content 0.5-0.8%, provide increased hardness but lack impact strength and are used in applications such as blades, springs and collars

- High carbon content steels Carbon content >0.8%, have a UTS >1GPa and are used where hardness is the primary property e.g. cutting tools, blades etc.

Conventional Method for Determining Carbon Content of Steels

The determination of the carbon content of steels is commonly carried out using something like a LECO carbon analyser. These instruments destructively test samples via combustion, measuring CO2 production using an IR detector to determine the carbon content.

Determining Carbon Content of Steels Using a Handheld LIBS

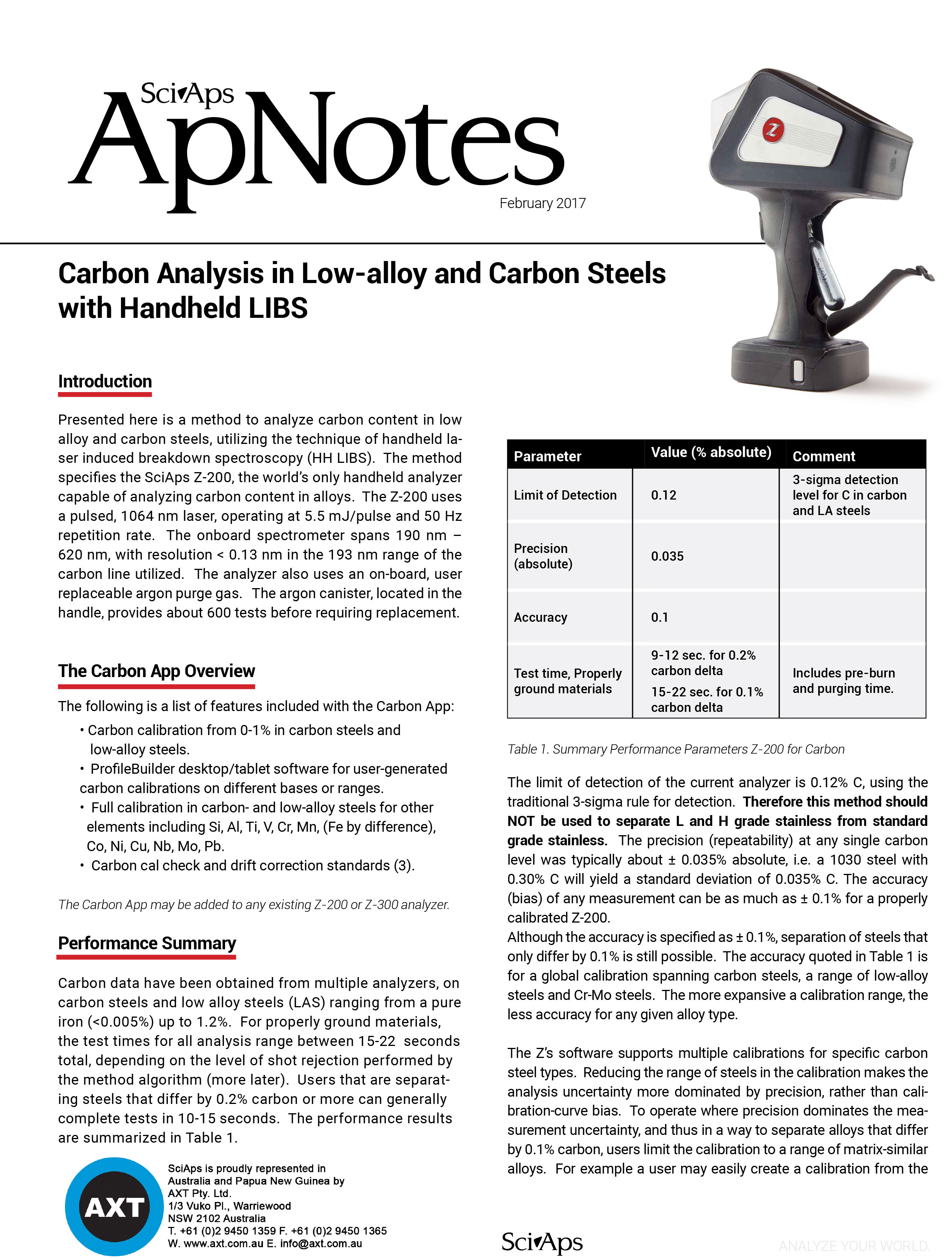

Presented here is a method to analyse carbon content in low alloy and carbon steels, utilising the technique of handheld laser induced breakdown spectroscopy (HH LIBS). The method specifies the SciAps Z-200, the worlds only handheld analyser capable of analysing carbon content in alloys. The Z-200 uses a pulsed, 1064 nm laser, operating at 5.5 mJ/pulse and 50 Hz repetition rate. The onboard spectrometer spans 190 nm 620 nm, with resolution < 0.13 nm in the 193 nm range of the carbon line utilized. The analyzer also uses an on-board, user replaceable argon purge gas. The argon canister, located in the handle, provides about 600 tests before requiring replacement.

How Does LIBS Work?

LIBS stands for Laser Induced Breakdown Spectroscopy. It works in a similar manner to Spark OES, but uses a powerful laser rather than an electrical spark. By blasting the surface of steel with the laser which removes very small amounts of material from the surface. As the particles are removed they form a small plume of plasma. As the plasma expands, the excited atoms in the ionised gas or plasma relax generating spectral emissions that can be detected by a spectrometer which can then be used to identify chemical elements.

Advantages of Handheld LIBS

Handheld LIBS has several advantages over combustion analysis. These include:

- No sample preparation requited

- The process is very inexpensive

- Completely non-destructive

- Highly portable enabling in situ testing