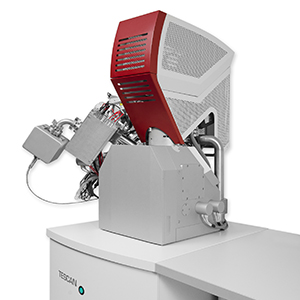

Model 1040 – NanoMill UHR TEM Sample Preparation System

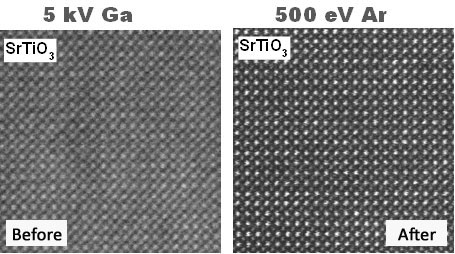

The NanoMill is a unique system that uses an ultra-low energy, concentrated ion beam enabling removal of amorphisation, implantation, or redeposition from targeted areas to produce the highest quality specimens for transmission electron microscopy.

Key Features

Key Features

Removes damaged layers and artefacts without redeposition

Removes damaged layers and artefacts without redeposition- Ideal for post-FIB processing

- Enhances the results from conventionally prepared specimens

- -170°C to RT NanoMilling SM process

- An Everhart-Thornley secondary electron detector (SED) for lamellae imaging 3mm FoV

- Real-time imaging

- Easy to maintain

Ion Source

- Ultra-low-energy, inert-gas ion source – 50 eV to 2keV

- Concentrated ion beam with scanning capabilities

- Adjustable beam size down to 1 ?m

- Filament-based ionisation chamber and electrostatic lenses.

- Variable working distance

- Controllable beam current/spot size

- Stable and repeatable ion beam using sophisticated control algorithms

- Scanning or point focussed beam

- Easily accessible for routine maintenance

- Highly precise and automated gas flow

- Integrated particulate filter ensures gas purity and preventing contamination

Specimen stage

- Programmable ion beam impingement angle – ?12° to +30° tilting stage

- Unique specimen holder provides unobstructed ion trajectories, even at 0°

- Mechanically affixed specimen eliminating sample contamination from adhesives

- Low angle milling (<10°) minimising irradiation damage and specimen heating

- Software controlled specimen holder and stage for optimised milling

- Liquid nitrogen cooled specimen stage for temperature-sensitive specimens

- <20 minutes to cool to -170°C

- Typically 4 to 6 hours operation using standard dewar

- Controlled heating to 20°C prior to venting

Chamber and Vacuum

- Rapid specimen exchange for high-throughput applications

- Contamination-free, dry vacuum system

- Automatic load lock for quick specimen transfer

- Direct viewing during transfer to and from the specimen stage

- Chamber light

Software and controls

Computer-controlled, fully programmable milling sequences

Computer-controlled, fully programmable milling sequences- Save recipes for repeatability

- NanoMilling process can be accomplished in as little as 20 minutes

- Easy to use operator interface

- Ion gun parameters i.e. energy, intensity and milling angle

- Sample positioning

- Scan speed, magnification, focus, brightness and contrast

- Temperature threshold

- Processing time

- Shortcut keys to speed programming and operation

- Automatic and manual termination

- Continuously monitored stage temperature

- Programmable thermal safeguard to automatically deactivate the ion gun

- Data and Error Logs for system review

- Administrator controlled user access privileges

- Programmable preventive maintenance alerts