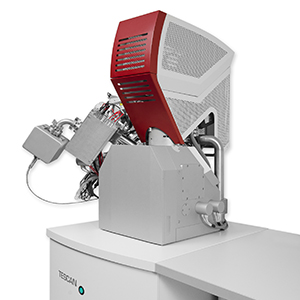

Model 1061 – SEM Mill for SEM Sample Preparation

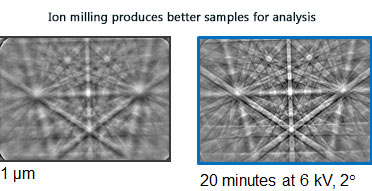

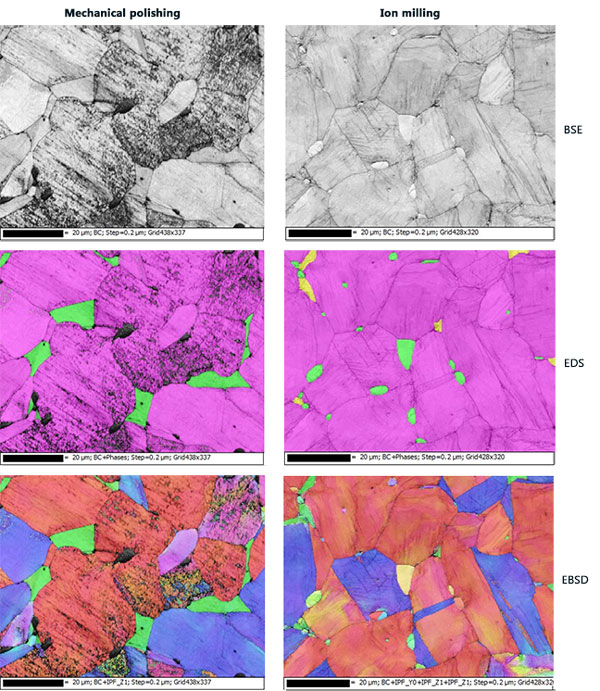

The 1061 is a state-of-the-art ion milling and polishing system for producing the highest quality SEM samples. Designed for creating pristine cross-section samples with the optional in situ Cross-section station.

Key Features

Key Features

- Two independently adjustable TrueFocus ion sources

- Independently adjustable beam diameters ~100% ionisation efficiency

- High-energy operation for rapid milling

- Low-energy operation for sample polishing

- Adjustable milling angle range of 0° to 10°

- Adjustable energy range from 100 eV to 10 kV

- Ion beam spot size range from 300 ?m to 5 mm

- Beam current density up to 10 mA/cm2

- Milling rates in excess of 500 ?m/hour

- Manual and extremely precise milling angle adjustment

Chamber & Vacuum system

Vacuum or inert gas transfer capsule (optional)

Vacuum or inert gas transfer capsule (optional)- In situ viewing and image capture during milling

- Microscope and camera options

- Fully integrated liquid nitrogen-cooled sample stage (optional)

- Quick sample transfer via a vacuum load lock

Sample Stage and Size

The SEM Mill accepts the following sample sizes:

- Cross section

- Maximum – 10 x 10 x 4.0 mm

- Minimum – 3 x 3 x 0.7 mm

- Planar

- 32 (dia) x 25 (height) mm

- Sample rocking or rotation

- Automatic sample thickness sensing for maximum throughput

- Magnetic encoding for absolute positioning accuracy.

Software

- Automatic and manual termination by time or temperature

- Touch screen control with a self-intuitive SW for automated, unattended operation and Programmable sample motion

- Software controlled ion beam energy, milling angle, specimen motion, specimen position, and process termination

- Adjustable 10-inch touch screen with a user-friendly interface for simple setup of milling parameters

- Allows for creating multi-step milling sequences including the automatic adjustment of milling angles throughout the milling process

- Other software features; Managing specimen data, maintenance and log files, and image storage, as well as remote access to oversee milling operations