X-Ray Fluorescence – XRF Spectrometers

X-Ray fluorescence (XRF) is a well-used analytical technique for determining the chemical composition of materials. It is suitable for material forms including solids, liquids, powders and coatings. For coatings, it can also be used to determine the thickness of the coating as well as compositional changes as a function of thickness, which is extremely useful for multilayer coatings.

The technique itself is relatively fast and can be carried out on samples with minimal preparation. It is capable of measuring the elemental composition of materials from 100% down to parts per million levels, with better detection limits for higher atomic number elements. Furthermore, XRF offers results with high levels of precision and repeatability which are easily achieved.

In terms of techniques for determining chemical composition, it is much faster and requires far less sample preparation compared to other traditional wet chemical methods such as atomic absorption spectroscopy (AAS) and Inductively Coupled Plasma Mass Spectrometry (ICP-MS). In many cases, samples can be used in an as-received state and do not require dissolution using potent acids.

Applications

The applications of XRF analysis are far reaching and span many different industries. Due to the versatility of the technique, the following is a non-exhaustive list of applications of XRF:

- Metals

- Cement

- Oil

- Polymers and plastics

- Food

- Mining and minerals

- Geology

- Environmental monitoring e.g. water sampling and waste analysis

- Pharmaceuticals

- Forensics

Sample Preparation

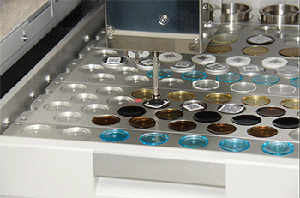

In many instances, XRF is used as a quality control tool, analysing small samples taken from very large production runs with results having a direct impact on production. For this reason it is important for the sample being measured to be representative of the entire run. XRF will only measure the composition of the surface layer, so it is important for the sample to be as homogenous as possible. Furthermore, the sample needs to be clean, with modern XRF spectrometers able to detect elements present in fingerprints and other contaminations.

While XRF can be carried out on as-received samples, best results are obtained using samples that have been optimised using some form of sample preparation. For solid materials like metals, sample preparation may just include polishing and cleaning.

For powder samples, they can be measured as:

- Loose powders in a sample cup using a supporting film such as mylar

- Pressed into pellets using such things as hydraulic sample presses

- Incorporated into glass beads using electric fusion machines, which yields homogenous samples

While being the most expensive method, fusion beads will produce the most accurate and reliable results. They achieve this by eliminating effects from mineralogy and gran size and reducing the effects of coexisting components through dilution. This technique can also be used to create standards from pure compounds.

See also: Selecting The Right Platinumware for your Automatic Fluxer

How Does XRF Work?

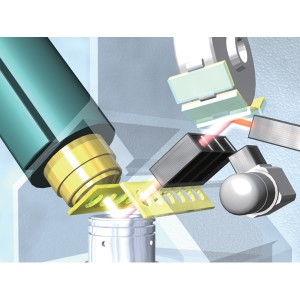

Specimens are exposed to x-rays generated by an x-ray tube. The elements present in the specimen emit fluorescent x-ray radiation with discrete wavelengths. The wavelength that each element emits is characteristic of that element.

By examining the wavelength of the emitted radiation it is possible to determine which elements are present. This is known as qualitative analysis.

By measuring the intensities of each emission, the amount of each element present can be determined. This is known as quantitative analysis.

XRF Spectrometers

XRF spectrometers fall into 2 categories based on their detection systems:

- Energy Dispersive X-Ray Fluorescence Spectrometers (EDXRF)

- Wavelength Dispersive X-Ray Fluorescence Spectrometers (WDXRF)

Energy Dispersive X-Ray Fluorescence (EDXRF)

The analytical range EDXRF covers Sodium (Na) to Uranium (U).

These systems use a detector that measures the different energies of the radiation that comes directly from the sample. It can separate the incoming radiation into the various elements present in the sample.

Wavelength Dispersive X-Ray Fluorescence (WDXRF)

WDXRF has a greater analytical range compared to EDXRF, and is sensitive to elements from Beryllium (Be) to Uranium (U).

WDXRF spectrometers employ an analysing (diffraction) crystal between the sample and the detector. The analysing crystal disperses the different energies and diffracts these energies in different directions.

WDXRF spectrometers come in three different configurations:

- Sequential spectrometers Use a detector mounted on a goniometer and measure the intensity of each wavelength one after another

- Simultaneous spectrometers Employ a set of fixed detection systems (crystals plus detectors) that are configured to detect emissions from specific elements and can measure each at the same time.

- Combined systems These systems use both fixed and moving detectors

Comparison of EDXRF and WDXRF Spectrometers

| WDXRF | EDXRF | |

|---|---|---|

| Elemental Detection Range | Be to U | Na to U |

| Spectral Resolution | Excellent | Good |

| Light Element Analysis | Excellent | Good |

| Rare Earth Analysis | Good | Difficult |

| Detection Limit | Optimised for all elements in the detection range | Good for light elements but suited better to heavy elements |

| Measurement Time* | Faster | Slower |

| Energy Resolution | Excellent ~20 to 150eV | Poor ~150eV |

| Power | Typically <4kW | Typically <1kW |

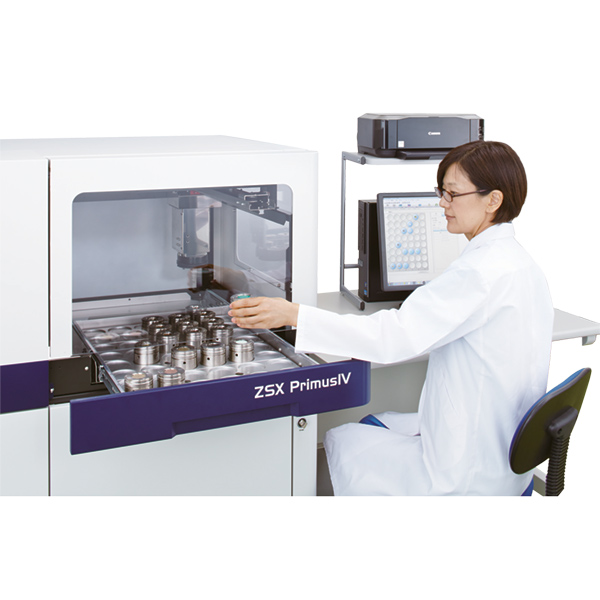

| Sample Capacity | High | Low |

| Automation | Easy | Difficult |

| Critical Moving Parts | Goniometer + Detectors | None to Few |

* Depending on the application.

XRD, The Perfect Partner for XRF

While XRF is a brilliant tool for determining the chemical composition of materials, it works very well hand-in-hand with X-Ray Diffraction (XRD). XRF is able to quickly and easily provide the elemental composition of an unknown. However, it is unable to determine the actual compounds that are present in a sample.

Example 1 – A sample might by XRF be shown to pure SiO2 by oxide analysis. SiO2 may exist in the crystalline forms as quartz, cristobalite or tridymite, or could even be present in an amorphous form such as fused silica. XRD can confirm the presence of theses phases.

Example 2 – A sample might contain a mixture of alumina (Al2O3), silica (SiO2) and sillimanite (Al2O3.SiO2). XRF will only be able to identify the presence of Al2O3 and SiO2. XRD is required to reveal the presence of the three phases.