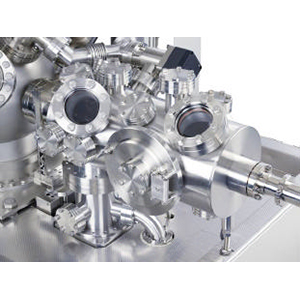

ESCALAB 250Xi X-Ray Photoelectron Spectrometer XPS Microprobe

ESCALAB 250Xi X-Ray Photoelectron Spectrometer XPS Microprobe

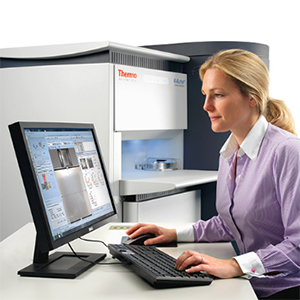

The Thermo Scientific ECSALAB 250Xi x-ray photoelectron spectroscopy XPS microprobe has been designed to meet the increasing demands and analytical performance of todays surface analysis researchers. It features high sensitivity, high resolution quantitative imaging and multi-technique capabilities.

The system itself can be expanded and configured to suit the users requirements providing high levels of flexibility. The ESCALAB 250XI combines cutting edge technology with intuitive hardware and softwareand best in class sensitivity and energy resolution to form a surface analysis solution for the most complex samples.

Optimised Performance

The ESCALAB 250Xi features a twin-crystal micro-focussing x-ray monochromator that delivers optimal XPS performance and facilitates maximum sample throughput. It is able to produce images with resolution better than 3µm, while the imaging detector delivers signature-free quantitative data.

Hardware

The x-ray monochromator uses an aluminium anode and has a sample spot size selectable in the range 200 to 900µm.

The lens/analyser/detector combination has been matched perfectly for optimal imaging and small area XPS. In addition, two detectors are integrated to suit imaging and high count spectroscopy along with a 180° hemispherical energy analyser.

The lens is equipped with two computer controlled iris mechanisms to allow the user control the field of view of the lens (down to <20µm), and the other to control angular acceptance of the lens which is essential for high quality angle resolved XPS.

Software

The Advantage data System controls all aspects of the system and enables the user to easily extract the maximum amount of data/information from the system. Features include:

- Integration of all aspects of analysis e.g. instrument control, data acquisition and processing and report generation

- Remote operation

- Interfacing with third party software

- Manages the entire process from sample preparation to report

- Digitally-controlled EX06 ion gun is a high-performance ion source even when using low energy ions

- Azimuthal sample rotation is available

- Multi-technique capability

- Other analytical techniques accommodated without compromise to the XPS performance

- Reverse power supplies for the lenses and analyser using the EX06 ion gun (ion scattering spectroscopy (ISS) is always available)

Depth Profiling

Multi-Technique Capability

The XPS microprobe has the versatility to allow the user to use a number of different analytical techniques including:

- XPS with non-monochromatic X-rays

- AES (Auger electron spectroscopy)

- UPS (Ultra-violet photoelectron spectroscopy)

The variety of analytical techniques, combined with a range of different sample preparation chambers makes the ESCALAB 250Xi the ideal solution for the vast majority of surface analysis scenarios.

Key Features

Key features of the ESCALAB 250Xi XPS microprobe include:

- High sensitivity spectroscopy

- Small area XPS

- Depth profiling capability

- Angle resolved XPS (ARXPS)

- Ion scattering spectroscopy (ISS) in base system

- Reflected electron energy loss spectroscopy (REELS) in base system

- Preploc chamber in base system

- Multi-technique analytical versatility

- Many sample preparation options

- Automated, unattended analysis

- Multiple sample analysis

Applications

Some examples of applications of the ESCALAB 250Xi XPS microprobe include:

- Examination of micromachined components

- Characterisation of ultrathin films without sputtering

- Chemical state imaging of carbon fibres on PET

- Measuring the surface chemistry of catalysts

- Characterisation of polymers and plastics

- Biosensors

- Monolayers

- Detection and analysis of contaminants

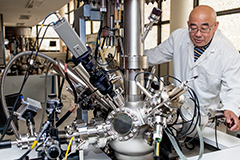

Surface analysis using X-ray photoelectron spectroscopy (XPS) is a unique method to measure the chemistry of very small quantities of material, typically it looks at the first 5-10 atomic layers of the solid surface. The technique provides elemental information, and even information on the chemical environment around an atom and its oxidation state. This type of data is normally only available from a synchrotron source.

Surface analysis using X-ray photoelectron spectroscopy (XPS) is a unique method to measure the chemistry of very small quantities of material, typically it looks at the first 5-10 atomic layers of the solid surface. The technique provides elemental information, and even information on the chemical environment around an atom and its oxidation state. This type of data is normally only available from a synchrotron source.

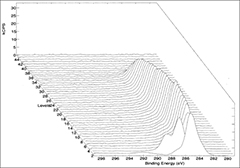

XPS analysis can be used with an ion source to etch minute craters in the sample to measure variations in chemistry with depth (see figure). The technique can also image the photoelectrons generated from a region of the surface to create maps of chemical distributions across the surface of a sample.

The University of New South Wales, Surface Analysis Laboratory hosts a state-of-the-art Thermo Scientific ESCALAB 250i that enables surface analysis for a diverse community of researchers, as well as research institutes and commercial organisations looking to solve problems in materials and engineering. They routinely measure semiconductor thin-films, metals, ceramics, polymers, composites, alloys, textiles, biomaterials and glass to better understand technologically important processes such as corrosion, catalysis, adhesion, friction and wear.

The University of New South Wales, Surface Analysis Laboratory hosts a state-of-the-art Thermo Scientific ESCALAB 250i that enables surface analysis for a diverse community of researchers, as well as research institutes and commercial organisations looking to solve problems in materials and engineering. They routinely measure semiconductor thin-films, metals, ceramics, polymers, composites, alloys, textiles, biomaterials and glass to better understand technologically important processes such as corrosion, catalysis, adhesion, friction and wear.

For more information on how the UNSW Surface Analysis Laboratory can help you, please contact Dr. Chris Marjo.

UNSW Breakthrough Brings Hydrogen Economy A Step Closer

Hydrogen has long been known to be a potential replacement for fossil fuels. Recently, researchers at UNSW have brought this possibility a step closer overcoming one of the scientific barriers that have stood in the way of realising the benefits of a Hydrogen economy. Details of their findings have been published in Nature Communications and The Australian.

The environmental and sustainability benefits of Hydrogen compared to fossil fuels are undeniable. Its abundance, being derived from water and pollution-free combustion producing only water make it an ideal candidate for powering cars, power stations and homes.

To be used as a fuel, hydrogen must be liberated from water using electrolysis which requires large amounts of energy and has been uneconomical to date. UNSW researchers Xunyu Lu and Chuan Zhao have recently fabricated new electrodes that go a long way to overcoming this issue.

The new electrodes that act as a catalyst are made from nickel foam coated with nickel-iron (NiFe) nanosheets. Dr Zhao says that these electrodes successfully not only address the problems of more traditional materials based on iridium and ruthenium which are both rare and expensive, but also outperform them requiring less energy to split water into hydrogen and oxygen.

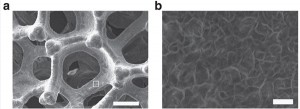

SEM shows that electrodes have a very open 3D structure (figure 1a). High resolution imaging reveals that the NiFe catalyst evenly coats the foam skeleton and has a ruffled nanosheet structure interconnected forming mesoporous nanostructures with pore sizes around 50nm (Figure 1b).

TEM and XRD results reveal that the NiFe catalyst had an amorphous structure. Hence a Thermo Scientific ESCALAB 250i XPS was required to determine its composition.

The XPS spectra showed that Ni, Fe and O were present in the catalyst suggesting a bimetallic composite had been deposited (Figure 2a). The Ni 2p spectrum (Figure 2b) reveals spin orbit peaks for Ni 2p1/2 and Ni 2p3/2 at 874 and 856eV respectively. These peaks also had shakeup satellite orbit peaks indicating that Ni was present in the Ni2+ oxidation state.

Moving to the Fe 2p XPS spectra (Figure 2c), Fe 2p1/2 and Fe 2p3/2 peaks appear at 725 and 712eV with a shakeup satellite at 720eV. This confirms that Fe is present in the 3+ oxidation state in the NiFe composite. By looking at the XPS spectra of the knife composite deposited into a Pt substrate the atomic ratio of Ni to Fe was determined to be 3, and hence the composition of the active catalyst derived to be Ni3Fe(OH)9.

Electrochemical testing of the NF/NiFe elctrodes showed them to have superior performance compared to the benchmark Ir-based catalysts. This was attributed to factors such as:

- The high catalytic activity of the NiFe nanosheet

- The unique hierarchically structured porous configuration providing a high surface area and excellent gas bubble dissipation

- Low electrical resistance of the entire water splitting cell by using the binder-free electrodeposition technique and high electrolyte concentration

UNSW is excited to announce that they have just commenced working with a commercial partner to further develop this technology and make it a reality.

Image Credits: Xunyu Lu & Chuan Zhao, Nature Communications 6, Article number 6616 doi:10.1038/ncomms7616

Image courtesy of Wikimedia Commons/Taisyo.