New Collaboration Set to Revolutionise Silicon Crushing

SELFRAG, a specialist in high voltage pulse power fragmentation, has joined forces with ALZTEC, provider of silicon processing systems to create a new breed of silicon rod crusher that minimises both waste and contamination. The first system will be delivered to a major customer at the end of 2014.

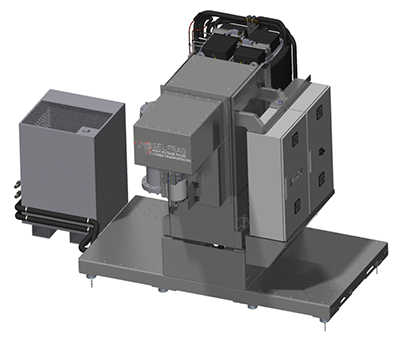

Swiss high-voltage fragmentation equipment manufacturer SELFRAG and German silicon processing specialist, ALZTEC, have developed an automated system for the high-purity crushing of silicon rods, wings, and offcuts. The system, combining SELFRAGs high purity fragmentation technology with ALZTECs material handling expertise, crushes up to two tons of silicon rods per hour with minimal mechanical contact.

Swiss high-voltage fragmentation equipment manufacturer SELFRAG and German silicon processing specialist, ALZTEC, have developed an automated system for the high-purity crushing of silicon rods, wings, and offcuts. The system, combining SELFRAGs high purity fragmentation technology with ALZTECs material handling expertise, crushes up to two tons of silicon rods per hour with minimal mechanical contact.

As each rod enters the system, it is submerged in water and blasted with 200,000 volts in a short burst, similar to a lightning bolt. This electrical discharge passes through the silicon rod, fragmenting the material into evenly-sized particles with limited risk of contamination.

Electrical fragmentation offers so many benefits to the silicon industry, says Frédéric von der Weid, CEO of SELFRAG. Its clean, more efficient and can significantly improve the profitability of our customers.

Reduced contamination

By minimising mechanical contact, the new high voltage fragmentation system reduces risk of contamination, facilitating higher and more consistent quality silicon.

Furthermore, the lower risk of contamination means limited or even no etching of the silicon is needed post-fragmentation. This not only helps speed up the process but also decreases the volume of etching chemicals required.

Size matters when crushing

Traditional mechanical crushing besides introducing unnecessary contaminants typically has a shearing effect on the rod, resulting in irregular needle-shaped pieces. In addition, the particle size distribution from mechanical crushing is hard to control and up to 12% of the material is rendered unsuitable for reforming. With SELGRAGs electrical fragmentation, however, almost all particles fall within the correct size class, limiting losses to less than 4%.

Electrical fragmentation also produces more rounded silicon particles with a better aspect ratio, which are easier to pack, reducing losses at that stage. Moreover, the rounded particles are more efficient to load into the furnace.

With reduced losses and increased efficiency including reduced energy consumption, SELFRAG and ALZTECs system can bring significant economic benefits to silicon producers. SELFRAG suggests that in a typical application the new system could even pay for itself in as little as nine months.

Powerful partnership

Our speciality is the development and commercialisation of high voltage pulse power fragmentation technology, says von der Weid. By partnering with ALZTEC, we are able to offer an entire rod processing system that can bring about a step change in the silicon industry. The considerable value proposition offered by our system is beginning to be recognised by the industry, with our first order to be delivered at the end of 2014.

Ernst Hopf, owner of ALZTEC says: We are delighted to incorporate SELFRAGs ground-breaking electrical fragmentation technology into our processing systems and by the huge advances that this project will offer our customers.

The electrical fragmentation system for silicon rods meets all European standards and is available for worldwide sale.

Posted September 17, 2014